In the high-stakes world of oil and gas production, reliability is non-negotiable. From drilling rigs to refineries, the equipment used in the oil and gas industry operates in some of the harshest and most challenging environments on the planet. That's why superior lubrication is essential to maximize uptime, minimize downtime, and extend the life of critical assets. At Certified Labs, we understand the unique demands of the oil and gas industry and are committed to providing innovative lubrication solutions to help you maintain operational excellence.

Elevating Performance in the Oil and Gas Sector

Certified Labs specializes in delivering advanced lubrication solutions that are specifically engineered to meet the rigorous demands of the oil and gas industry. Our products are designed to withstand extreme temperatures, pressures, contamination, and corrosive substances encountered in drilling, extraction, transportation, fracking, and refining operations. Whether it's protecting drilling equipment from wear and corrosion or ensuring the smooth operation of pumps, compressors, power ends, and turbines, our lubricants are formulated to deliver exceptional performance and reliability in the most challenging environments.

Why Choose Certified Lubricants?

- • Industry Expertise: With years of experience serving the oil and gas industry, Certified Labs understands the unique lubrication needs and challenges faced by our customers.

- • Advanced Formulations: Our lubricants are formulated using the latest technology and highest quality base oils and additives to deliver superior performance, reliability, and protection in even the most demanding applications.

- • Customized Solutions: We offer a comprehensive range of lubrication solutions tailored to meet the specific requirements of different equipment types, operating conditions, and industry standards.

- • Technical Support: Our team of lubrication specialists are dedicated to providing expert advice and support to help you optimize your lubrication practices and achieve maximum efficiency, productivity, and reliability.

Whether you're operating in upstream exploration and production, midstream transportation and storage, or downstream refining and processing, Certified Labs is your trusted partner for peak performance in the oil and gas industry. Contact us today to learn more about how our advanced lubrication solutions can help you increase uptime, improve equipment life, and maximize the efficiency and reliability of your operations. Together, let's fuel success in the oil and gas industry.

Value Recognition Report

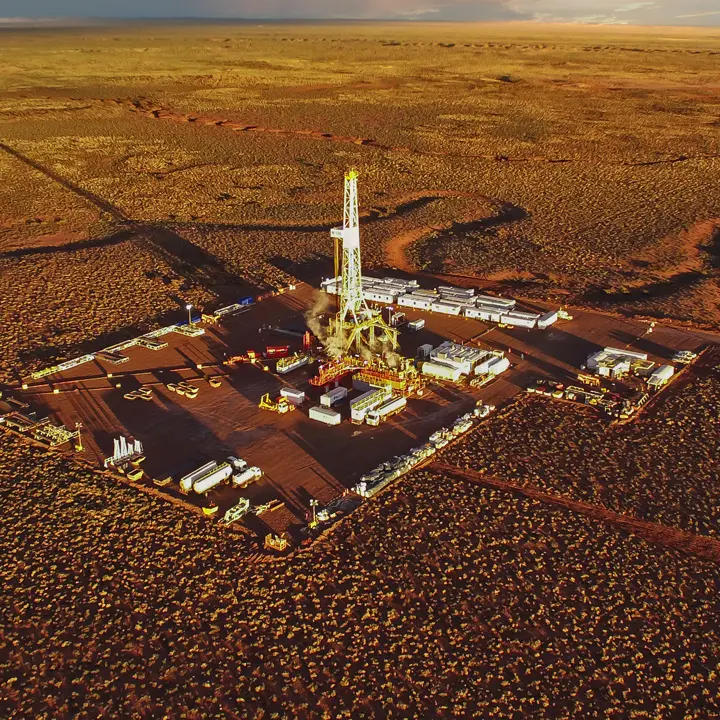

Hydraulic Fracturing Services

Customer Profile: Their goal is to establish a partnership to ensure safe and successful well completions. With their combination of experienced personnel, top of the line equipment, extensive maintenance, and streamlined logistics they can deliver pumping operations that will increase the overall productivity of wells in a cost and time effective manner. Currently operating in the Utica Shale, their team has extensive knowledge of the region allowing them to meet and exceed the design and execution needs. The company currently operates and maintains 52 pumps.

Certified's Objective: Provide a performance lubrication program to extend drain interval and engine life and deliver exceptional protection on the company’s equipment. After switching to Certified’s Certop, Spectra Xtreme 15W-40 Motor Oil, and TO-4 Transmission oil. Stingray’s power ends are now lasting 1000+ hours, while extending drain intervals on their power units and transmissions to 750+ hours.

Power Ends Costs: $717,631.20

Power Units Costs: $428,188.80

Transmissions Costs: $173,334.72